Introduction

Anodizing is an advanced electrochemical process that enhances the surface properties of metals, especially aluminium by forming a controlled oxide layer. This protective coating improves corrosion resistance, surface hardness, and appearance, making anodizing one of the most popular surface finishing techniques in manufacturing, construction, aerospace, and consumer electronics.

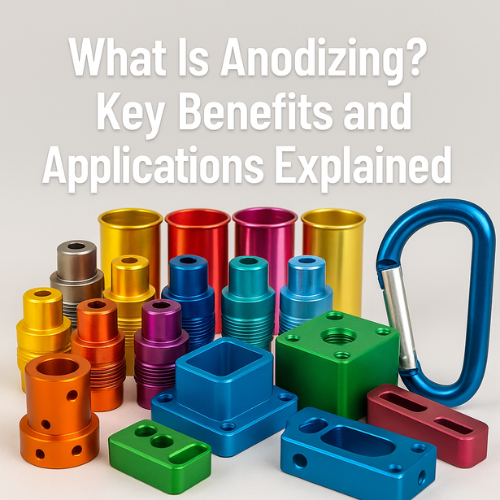

The process not only boosts durability but also allows aesthetic flexibility, with finishes ranging from natural metallic shades to vibrant colours. Let’s explore how anodizing works, its advantages and disadvantages, and its practical uses across industries.

What Is Anodising and How Does It Work?

Anodizing is essentially a controlled oxidation process. The metal part, typically aluminium, is submerged in an acid electrolyte bath (commonly sulfuric acid) and connected to the positive terminal of an electric circuit, turning it into the anode. A cathode is also placed in the bath, and when electric current passes through, oxygen ions are released from the electrolyte. These oxygen ions bond with the metal surface, forming a hard, porous layer of aluminium oxide.

Unlike paint or plating that merely sits on the surface, anodizing integrates the oxide layer into the base metal itself. This makes the coating extremely durable and resistant to chipping, peeling, or corrosion.

The anodized layer also has microscopic pores, allowing dyes or metallic salts to be absorbed for colouring. Finally, the surface is sealed using hot water or chemical sealing, locking in the colour and closing the pores to prevent contamination and corrosion.

Key Benefits and Advantages of Anodising

1. Enhanced Durability and Corrosion Resistance

Anodized aluminium forms a barrier against environmental damage. The oxide layer protects the metal from oxidation, moisture, salt, and chemicals, extending the lifespan of the part; especially in marine or industrial environments.

2. Long-Term Colour and Finish Stability

Because the dye is sealed within the oxide layer, anodized surfaces retain their colour even when exposed to UV rays or extreme temperatures. Unlike painted surfaces, they don’t flake or fade easily.

3. Ease of Maintenance

Anodized surfaces require minimal upkeep. Regular cleaning with mild soap and water restores their shine. Their scratch resistance also reduces the need for frequent refinishing.

4. Aesthetic Versatility

Anodizing supports a wide range of finishes—from matte and satin to glossy metallic looks—and can be tinted in multiple colours. This versatility makes it a favorite for architectural facades, decorative panels, and consumer electronics.

5. Environmentally Friendly Process

The anodizing process produces no hazardous by-products and uses non-toxic materials. It is also energy-efficient compared to other metal finishing methods like plating or painting.

6. Excellent Adhesion and Coating Compatibility

The porous oxide surface improves adhesion for paints, glues, and coatings. This makes anodized aluminium ideal as a base for further decorative or functional coatings.

7. Safe and Chemically Stable

Anodized coatings are non-toxic, non-reactive, and heat-resistant up to the melting point of aluminium (around 660°C). This stability ensures safe use in consumer and industrial applications.

Applications of Anodizing Across Industries

1. Construction and Architecture

Anodized aluminium is extensively used in building facades, windows, curtain walls, and doors. It resists weathering, maintains colour over decades, and provides a sleek, modern appearance without frequent maintenance.

2. Aerospace and Automotive

In aerospace, anodized aluminium components such as fuselage sections, brackets, and fasteners resist corrosion and reduce weight without compromising strength. In automotive applications, it is used for engine parts, trims, and wheels to improve wear resistance and aesthetics.

3. Consumer Electronics

Smartphones, laptops, and audio devices often feature anodized aluminium casings for their premium look and scratch resistance.

4. Industrial and Mechanical Components

Anodized parts like valves, pistons, heat sinks, and machine housings benefit from the process due to enhanced surface hardness, reduced friction, and longer service life in high-stress environments.

5. Decorative and Artistic Uses

Beyond engineering, anodizing is used for decorative panels, lighting fixtures, signage, and furniture, where both beauty and durability matter.

Real-Life Anodizing Examples

- Aerospace manufacturers use hardcoat anodizing (Type III) on aircraft components to withstand extreme temperatures and corrosion.

- Electronics producers use colour anodizing for stylish finishes and brand differentiation in devices like tablets and laptops.

- Architectural designers prefer anodized cladding for sustainable, low-maintenance building exteriors that retain luster for decades.

Conclusion

Anodizing is far more than just a protective coating, it’s a transformation of metal at the molecular level. Its combination of durability, beauty, and environmental sustainability makes it indispensable across industries from aerospace to architecture. Despite some limitations in material compatibility and cost, its long-term performance and minimal maintenance make anodizing one of the most efficient and value-driven finishing processes available.

Whether enhancing a precision aerospace part or creating an elegant smartphone shell, anodizing remains the gold standard in metal finishing for strength, longevity, and style.