In modern interiors and lifestyle products, appearance alone is not enough. Surfaces must look premium, remain durable, resist wear, and perform reliably over time. This is where spray lacquers play

Continue reading

In modern interiors and lifestyle products, appearance alone is not enough. Surfaces must look premium, remain durable, resist wear, and perform reliably over time. This is where spray lacquers play

Continue reading

In today’s competitive manufacturing and design landscape, surface finishing is no longer just about making products look good. It is about protection, performance, durability, consistency, and sustainability. This is where

Continue reading

GEOMET® Chrome-Free High-Performance Corrosion Resistant Technology Used in the Automotive Industry Corrosion protection is critical in the automotive industry, where components constantly face moisture, road salt, heat, chemicals, and mechanical

Continue reading

The aerospace industry demands materials that can survive extreme environments while maintaining structural integrity, dimensional stability, and long-term reliability. Aluminium and its alloys are widely used because of their excellent

Continue reading

The automotive industry is undergoing a major material transformation driven by stricter emission norms, electrification, light weight requirements, and long-term durability expectations. Among surface engineering technologies, anodizing of aluminium has

Continue reading

The automotive industry is shifting rapidly towards lighter, more efficient, and more sustainable materials. Anodized aluminium has emerged as a key technology in car manufacturing because it offers a rare

Continue reading

Applications of the Colouring Process in Anodizing Aluminium Aluminium is one of the most versatile and widely used metals across industries—from aerospace to consumer goods. One process that significantly enhances

Continue reading

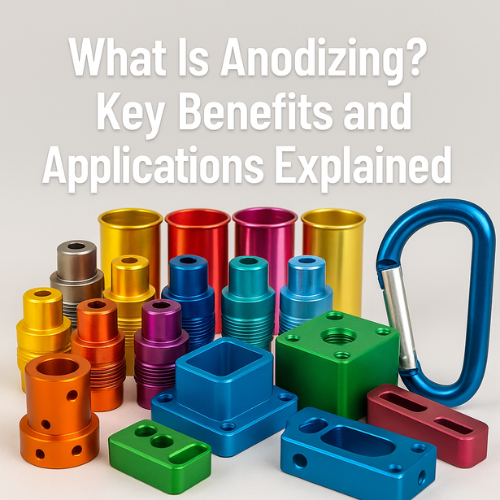

Introduction Anodizing is an advanced electrochemical process that enhances the surface properties of metals, especially aluminium by forming a controlled oxide layer. This protective coating improves corrosion resistance, surface hardness,

Continue reading

Solar energy is revolutionizing the global power landscape — and at the heart of every photovoltaic (PV) system lies a framework of engineered materials designed for efficiency, durability, and sustainability.

Continue reading

As design trends shift toward minimalist, modern, and sustainable aesthetics, the materials used in furniture and furnishings are evolving too. Among these, anodized aluminum has emerged as a frontrunner in

Continue readingCall Us Now

Phone: +91 22 66993000

Send a Message

Support: corporatecommunications@growel.com

Main Office

Growel Corporate, Akurli Road, Kandivli (E),

Mumbai - 400 101, Maharashtra, India

Grauer & Weil (India) Limited © 2022.