Overall, the most typical utilization of a lubricant is to decrease interference among the two surfaces, but remember every lubricant has some differences. Here given are the common lubricants and

Continue readingAuthor: Groweladmin

Everything You Want To Know About The Future of Global Wire Drawing Lubricant Market?

Lubrication in the drawing method is necessary for sustaining good exterior polish and extended die life. These two are the specific methods for lubrication; Wet drawing – in this the

Continue readingNew Painting Technologies That You Need to Know About

Are you planning to paint your house shortly? Are you confused about the best shades which would offer a dazzling finish to your walls? If these are related to you,

Continue readingAll You Need to Know About Pipe Coatings

Many companies need to deal with underground pipes meant for the transmission of gases, oil, or water. They remain buried underground, and often experience damages due to corrosion, or coming

Continue reading

A Look into the Evolution of Pipeline Coatings

This growth in gas exploration has initiated new markets for pipeline coatings and joint coating materials as evaluations of pipeline construction in Pennsylvania. Here given are the descriptions of coating

Continue readingWhy Indian Paint Companies Are Shifting To Water Based Paints

Most of the paint companies in India have taken a massive transition from the solvent-based paint to water-based paints for much better performance. Because of the much-increased input cost of

Continue readingWhy Protective Industrial Coatings Are Important

Protective Industrial Coatings are very important and beneficial as they can be used in vast industrial applications. They are protective and also safeguard your pipes against external hazards. Protective Industrial

Continue readingAll You Need To Know About Pipe Coating

Pipe coating is a very effective solution for preventing pipes from corrosion by air or moisture and from external agents like chemicals and hazardous substances. Coated pipes are very effective

Continue readingWhy Copper Pipe Protective Coating Is Important

Pipes have countless use in the home; most of them are arranged due to the introduction of pipes. For comfort, pipes play an essential role. Even you had a system

Continue readingBenefits Of Using High-Quality Lubricants

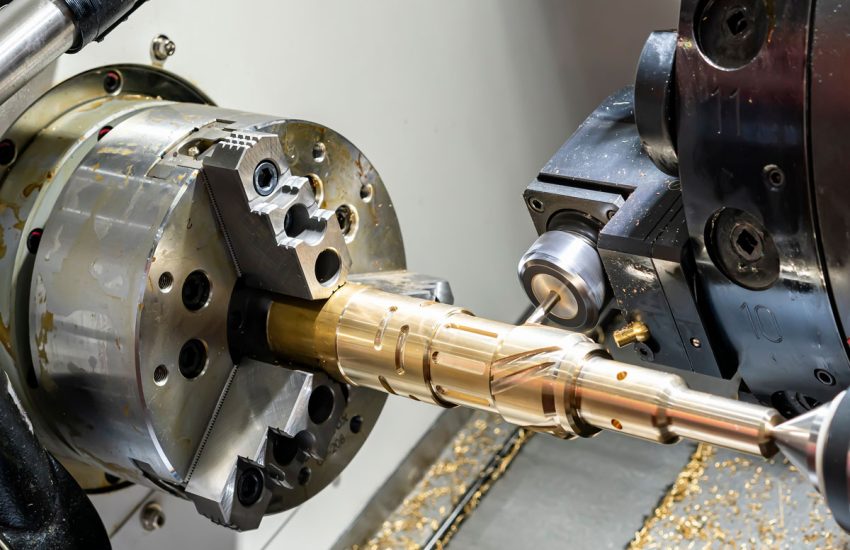

Wire drawing process includes the use of metal, which reduces the cross-section after it goes through a series of dies. This is the type of forging process that is plastic,

Continue reading