GINPLATE NI 4320 AutoP is a Midphos, self-pH-regulated electroless nickel-plating (ENP) process, which provides a mirror bright finish.

Midphos ENP is commonly used on components exposed to mild environment for corrosion/wear resistance with an aesthetic appearance.

Electroless Nickel plating is an auto catalysed redox process that deposits an even layer of Nickel-phosphorus alloy coatings on a properly prepared surface. pH plays an important role in any redox process and it tends to change during the course of the chemical reaction due to generation of H+/OH– ions in the reaction vessel. During electroless nickel plating, the pH drops down due to generation of H+ ion, which needs readjustment by adding Ammonia or other base to maintain the alloy composition and plating speed. Hence, an auto-pH-regulated ENP process was a long-standing demand of ENP platers.

GINPLATE NI 4320 AutoP is specially designed to produce a consistent midphos EN deposits at a very good plating speed without any additional replenishment of Ammonia. The carefully formulated additives and buffer system of GINPLATE NI 4320 AutoP provides an excellent pH and bath stability without compromising the quality and speed of the plating. Mid Phosphorus ENP acts as a low-cost alternative for decorative and functional applications.

The GINPLATE NI 4320 AutoP is supplied as three separate liquid concentrates: GINPLATE NI 4320 AutoP A, GINPLATE NI 4320 AutoP B, and GINPLATE NI 4320 AutoP C.

CHARACTERISTICS OF COATING

- Self-pH-Regulated process

- Robust and Hybrid buffer system

- Good plating Speed (15 – 22 μ/hr)

- Phosphorous content 4.5 – 8.5% w/w)

- Mirror bright finish

- Long bath life (10 MTO)

- Low operating cost

- Good wear and abrasion resistance

- Suitable for plating on wide variety of substrates, SS, MS, CS, Cu alloy & Al alloy

- P-Content may be fine-tuned and controlled as per requirements of jobs.

- Magnetic Deposit (<8.5% P-content)

ADVANTAGES

- No Ammonia is required to maintain the pH. Low maintenance cost and easier to maintain plating speed and alloy composition due to constant and consistent pH over the longer bath age.

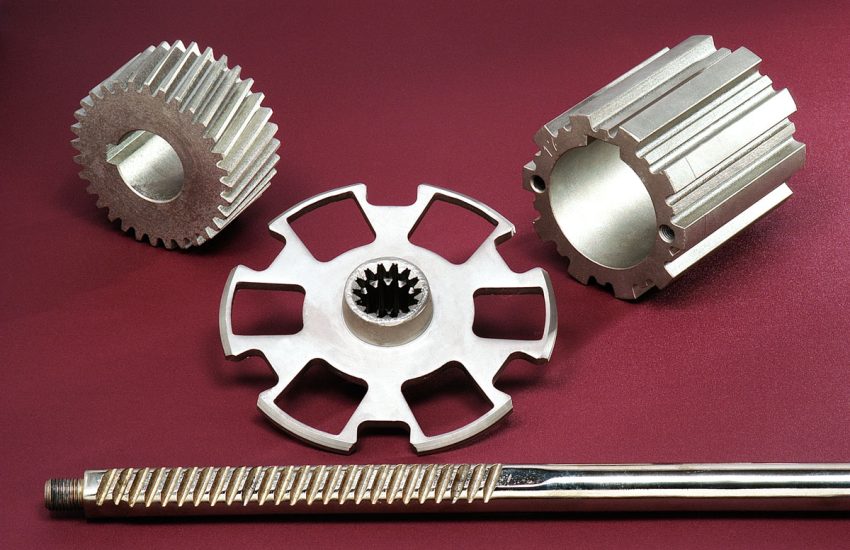

- Uniformity, hardness and corrosion/wear resistance makes it ideal for the parts or components that function under constant pressure or dynamic condition.

- Plating with ENP can often eliminate the need for machining or polishing due to its good surface finish and uniform thickness distribution.

- Midphos ENP provides large flexibility of thickness, volume, and alloy composition of the plating on metal/conducting surface. It can easily fill recesses or pits on the metal surfaces. This allows its application in a wider variety parts of industrial applications.

APPLICATIONS

- Chemical process industry

- Medical and food processing industries

- Aerospace Industries

- Hydraulics

- Tools and engineering instrument

- Oil and gas industry

- Automobile industry