At Growel, automation is at the heart of all our plating plants. Keeping this in mind our team, in technical collaboration with Utikal Automation Germany, is working with GalvCon V4.0,

Continue readingCategory: industrial lubricant

GRODAL GLASS 339 – Glass Grinding Fluids Challenges & Opportunities

In the early days of glass processing, water was used as a coolant and lubricant. However, the use of diamond-tipped tools in glass processing with only water as a coolant

Continue reading

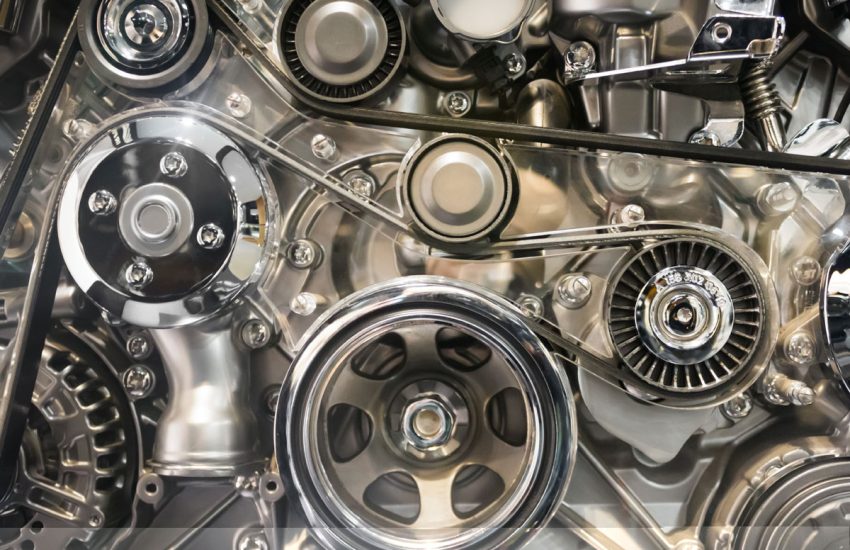

How Choosing The Right Lubricant Can Reduce Equipment Costs?

Lubricants are largely used in industries. Lubricants are substances that are used to reduce friction between surfaces. Different types of lubricants are used to improve the performance of machines and

Continue reading

Importance of Industrial Lubricants in India

The Indian lubricant industry has recently opened up new markets. The strong growth in India’s energy, engineering, and automotive sectors is a boon for lubricant manufacturers. In the automotive sector, as consumers migrate to efficient vehicles and motorcycles, they

Continue reading

How to Choose The Right Lubricant Companies in India?

Did you know that choosing the right lubricant supplier for your machine guarantees the operational success of your company? Well, the majority are unaware of this fact. Keep in mind

Continue reading

5 Tips to Evaluate Lubricant Companies in India

Lubricant oils are highly used substances that help to reduce friction between solid surfaces. Different types of lubricants are largely used across various industries as they improve the performance of

Continue reading

3 Things to Consider While Evaluating Lubricant Companies

Lubricant oils are substances that help in the reduction of friction and heat between solid surfaces to make the movement efficient. Lubricant oil lubricates the machine parts, improves efficiency, and

Continue readingWhat Are The Different Types Of Lubricants And Their Uses?

Overall, the most typical utilization of a lubricant is to decrease interference among the two surfaces, but remember every lubricant has some differences. Here given are the common lubricants and

Continue reading

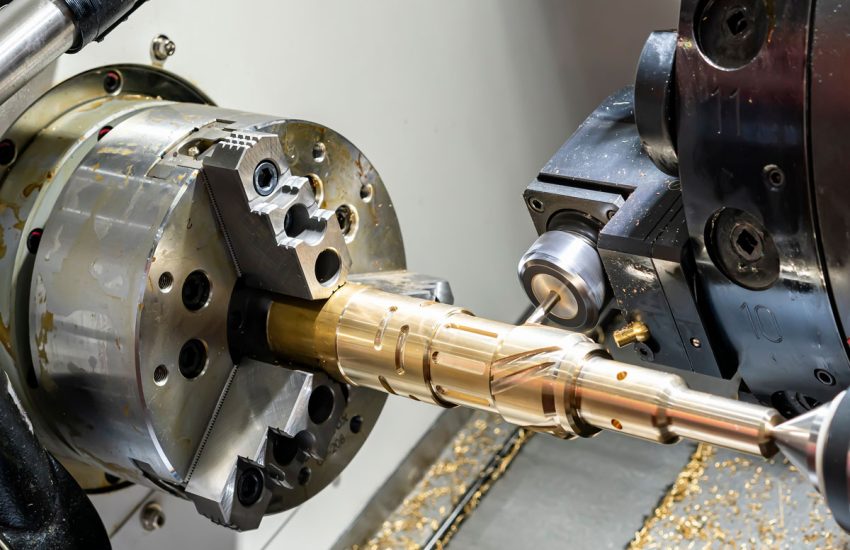

Everything You Want To Know About The Future of Global Wire Drawing Lubricant Market?

Lubrication in the drawing method is necessary for sustaining good exterior polish and extended die life. These two are the specific methods for lubrication; Wet drawing – in this the

Continue readingNew Painting Technologies That You Need to Know About

Are you planning to paint your house shortly? Are you confused about the best shades which would offer a dazzling finish to your walls? If these are related to you,

Continue reading