Lubricant oils are highly used substances that help to reduce friction between solid surfaces. Different types of lubricants are largely used across various industries as they improve the performance of

Continue reading

Lubricant oils are highly used substances that help to reduce friction between solid surfaces. Different types of lubricants are largely used across various industries as they improve the performance of

Continue reading

Lubricant oils are substances that help in the reduction of friction and heat between solid surfaces to make the movement efficient. Lubricant oil lubricates the machine parts, improves efficiency, and

Continue readingOverall, the most typical utilization of a lubricant is to decrease interference among the two surfaces, but remember every lubricant has some differences. Here given are the common lubricants and

Continue reading

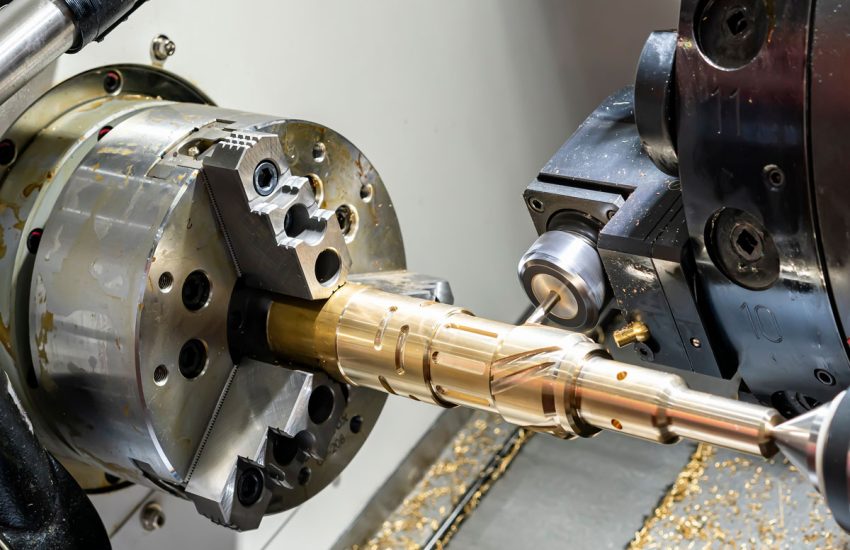

Lubrication in the drawing method is necessary for sustaining good exterior polish and extended die life. These two are the specific methods for lubrication; Wet drawing – in this the

Continue readingAre you planning to paint your house shortly? Are you confused about the best shades which would offer a dazzling finish to your walls? If these are related to you,

Continue readingMost of the paint companies in India have taken a massive transition from the solvent-based paint to water-based paints for much better performance. Because of the much-increased input cost of

Continue readingProtective Industrial Coatings are very important and beneficial as they can be used in vast industrial applications. They are protective and also safeguard your pipes against external hazards. Protective Industrial

Continue readingWire drawing process includes the use of metal, which reduces the cross-section after it goes through a series of dies. This is the type of forging process that is plastic,

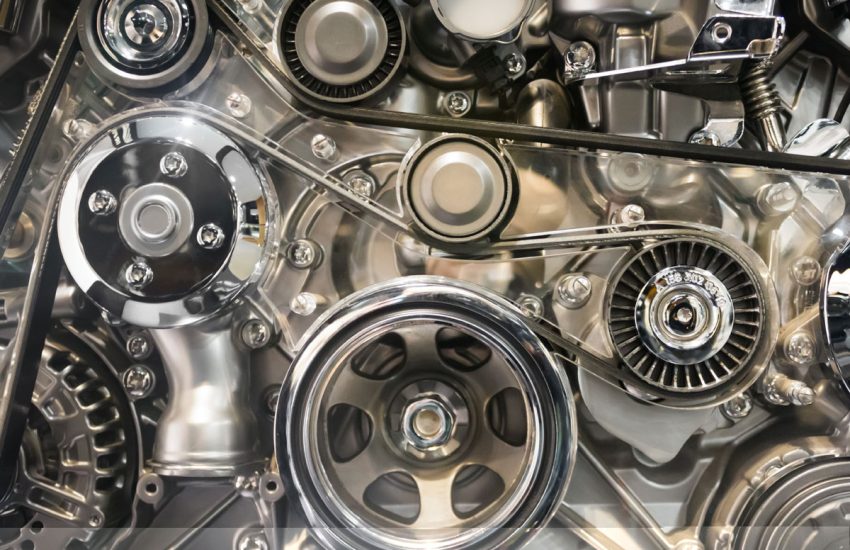

Continue readingAs an owner of the car, you must understand certain things that enhance the life of your vehicle, especially its engine. An automobile is expensive asset that cannot be left

Continue reading

Sub-standard lubricity results in die wear which leads to poor wire quality and wire breaks, thus reducing productivity and increasing operating costs. There are famous manufacturers of copper wire drawing

Continue readingCall Us Now

Phone: +91 22 66993000

Send a Message

Support: corporatecommunications@growel.com

Main Office

Growel Corporate, Akurli Road, Kandivli (E),

Mumbai - 400 101, Maharashtra, India

Grauer & Weil (India) Limited © 2022.