Automobiles, by design, feature metallic parts which are prone to the elements of dust, water and temperature. Corrosion resistance then becomes indispensable. In such a scenario, OEMs must use chemically

Continue reading

Automobiles, by design, feature metallic parts which are prone to the elements of dust, water and temperature. Corrosion resistance then becomes indispensable. In such a scenario, OEMs must use chemically

Continue reading

The history of the zipper is fascinating. It is the sole reason why Levi’s blue jeans came into existence. It holds everything together, from leather jackets to boots, from winter wear to

Continue reading

The garment industry constantly evolves, with new fashion trends emerging regularly. A versatile tool, zippers are employed in haute couture, business to casual wear, as well as footwear and bags.

Continue readingDifferent advantages of zinc aluminum flake coating are as follows : No Hydrogen embrittlement – The treatment process of zinc aluminum flake coating do not involve treatment with acid for

Continue reading

GINPLATE NI 4320 AutoP is a Midphos, self-pH-regulated electroless nickel-plating (ENP) process, which provides a mirror bright finish. Midphos ENP is commonly used on components exposed to mild environment for

Continue readingUse of ferrous and non- ferrous material is unavoidable in the industry due to its availability, strength, durability, work-ability and ability to recycle. Automobiles, bridges, house- hold appliances, power generation

Continue reading

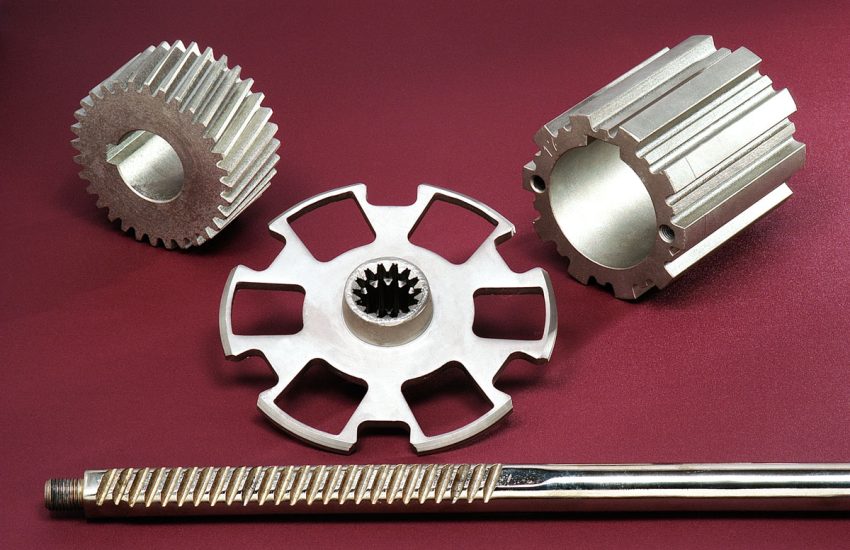

Electroless Nickel Plating (ENP) is the deposit of a nickel-phosphorous alloy coating by autocatalytic chemical reduction – without the electric current. The majority of ENP for engineering purposes is a

Continue readingGrowel Specializes in the development & manufacture of lubricating oils used in the wire drawing industry. The Indian Market hitherto was dominated by multinational corporations, Growel drawing oil has developed

Continue readingGrodal Syncool 2 is the “GROWEL” make surface protector cum coolant widely used in Pump Industry for Submersible / Open well / Self Priming Pump-sets. Its primary application is to

Continue readingAt Growel, automation is at the heart of all our plating plants. Keeping this in mind our team, in technical collaboration with Utikal Automation Germany, is working with GalvCon V4.0,

Continue readingCall Us Now

Phone: +91 22 66993000

Send a Message

Support: corporatecommunications@growel.com

Main Office

Growel Corporate, Akurli Road, Kandivli (E),

Mumbai - 400 101, Maharashtra, India

Grauer & Weil (India) Limited © 2022.